A coolant flow meter helps reduce overheating in firms and acts as a water saver when the setup is turned off and saving resources for firms.

A coolant is a fluid used in cooling a hot system. The coolants are popular with a machine such as lasers that can quickly overheat if the heat is not reduced promptly. Some of the coolants used are cooling water and glycol that can easily freeze a regular setup if used in them.

The machine that needs coolers covers chillers and lasers that would break down if they overheat due to a fault. Also, an exact amount of the fluid going through such a system needs to be continuously monitored to sense any leaks that would put the system down or lead to a safety issue. Some of the fluids used as coolants are poisons into the environment.

Looking at the liquids used, one would expect that the flow meters used to gauge the flow rate must not be mechanical to avoid freezing the parts in the meter. A coolant flow meter is meant for the rugged conditions that other meters can't handle.

Coolant control involves all of the tools and acts leading to gauging and regulating the coolant flow rate to maintain a stable heat to keep hot machines going. Folk must get it right when using the Welsaver flow controller and leak detector.

Pros of coolant control

Automation

Most of the flow meter things to ensure that the fluid is in check are done automatically without human intervention. That saves labor costs in firms and helps keep everything under control in a hard time.

Low Cost

While many people look at getting a new flow meter to control the coolant as a cost, it reduces running a system. You do not have to repair the machines regularly due to overheating or the coolant freezing in the pipe and leading to breakage.

Safety

A coolant is often cold while the device it regulates is hot. If you were to touch either of the two, you could have frostbite or sustain burns. If the machines also overheat, it could lead to breakage or in factories with hot fluid; this could mean big accidents.

Flow control helps check for excesses in the system regarding flow rate and extreme heat and keep them in check. The system can also issue alarms that the user can then handle any severe issues.

Types of Flow Meter Used

Thermal flow meter

The most common coolant flow meter is the thermal mass flow meter. The meter has two sensors, one to check the heat in the fluid and check the coolant's heat. If there is a great heat difference, the flow rate of the coolant is increased.

One can get the flow rate of the fluid in the meter by use of the temperature difference. This meter is crucial in places where scalding liquids are used, like molten superconductors; the coolant flow meter is used with robotic arms in this firm.

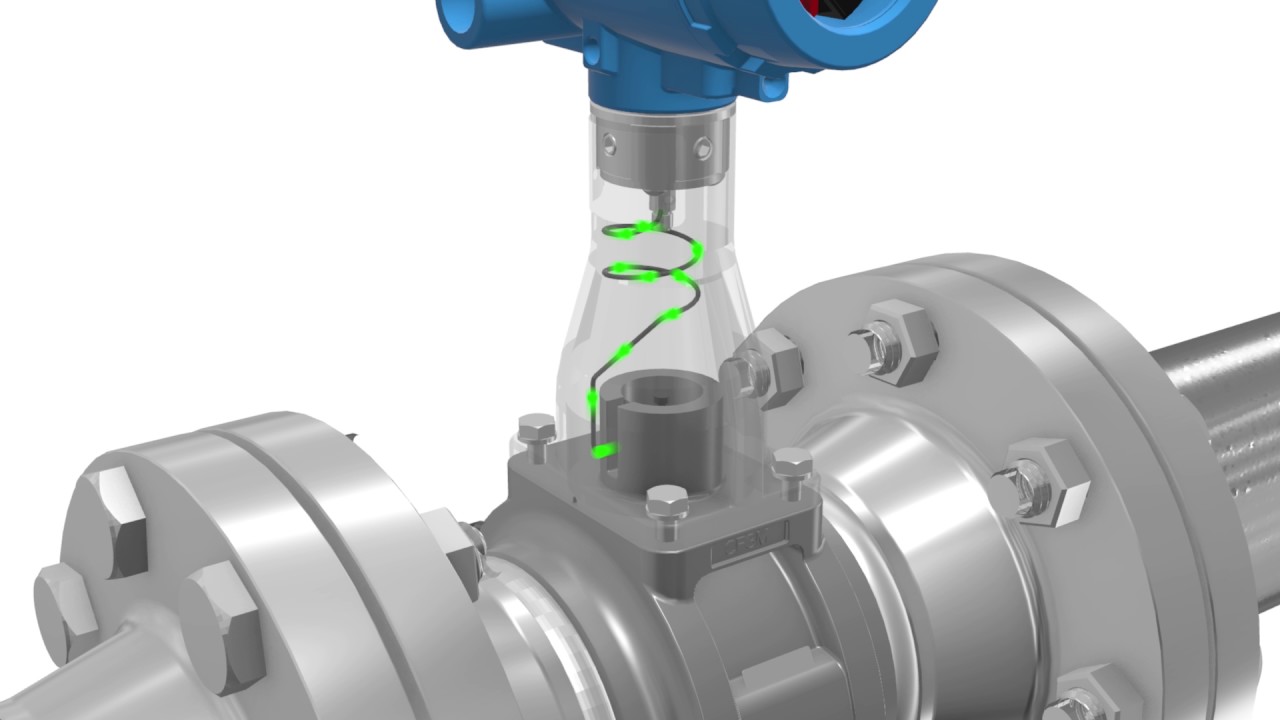

Vortex Flow Meter

The vortex meter has also gained heavy use in coolant control. Coolant Flow Controller & Leak Detector has been used in the car industries to protect welders from overheating.

Final word

A coolant flow meter helps reduce overheating in firms and acts as a water saver when the setup is turned off and saving resources for firms. The Weldsaver also keeps the machines at an ideal heat rate to work efficiently.