Metal manufacturing has been existing for many centuries now. From traditional methods that were employed in the beginning that make use of antiquated materials, fabrication has gone beyond to incorporate technological advancements.

Innovations have led to the discovery of novel ways of incorporating different materials like steel, as well as, improving on its properties. As a result, many steel products have been manufactured.

As one of the most versatile materials, it would be a disservice to not take advantage of the many features of steel in the manufacturing process. It’s likely that industries have only scratched the surface when it comes to harnessing all the benefits of steel. Keeping this in mind, metal production is continually accommodating many new ways of improving efficiency in the way processes are done. Continue reading to learn more.

Automated manufacturing

One trend that manufacturing industries are likely currently gearing towards, is the gradual focus on automated manufacturing processes. As you may already be well aware, there are different fabrication processes that make use of complicated equipment in order to cut or alter the appearance of metal.

It won’t be surprising to find that current processes still make use of manual methods, especially regarding quality control and equipment operation. However, automation will likely become the standard in the next coming years. There would be an increase in demand for more efficient techniques that are less time-consuming and results in less byproducts or waste material.

Automated manufacturing also entails the need to subject equipment operators to adequate training to align their skills to the new methods. Subsequently, automation also assists in improving the overall quality of workplace safety in these types of sites.

Tube laser technology

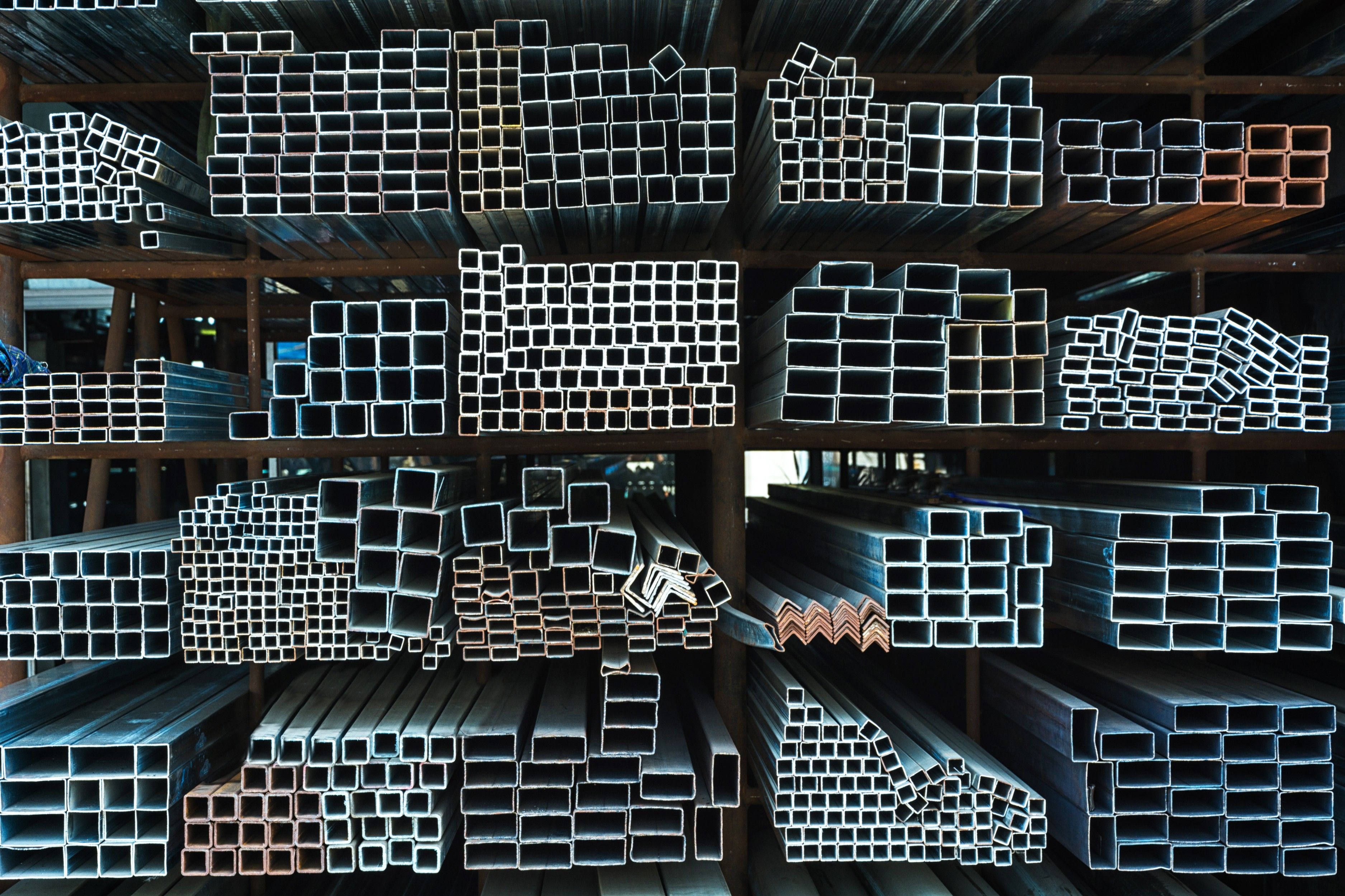

Tube laser is another type of metal fabrication process. In particular, this refers to laser technology being applied to tube metal products, which were previously applied to sheet metals.

Laser technology is nothing new as it has been employed in cutting up materials which aren’t necessarily made of metal. The process usually involves a non-contact form of cutting that is made possible using an advanced and high-powered form of laser technology. On the surface, utilization of laser technology makes the production of cutting-edge materials that are precise in sizing and dimensions. There’s no need for secondary processes that do the job of further refining the metal before the distribution proper.

End-users of tubing materials such as fittings and pipes would be advantaged with the use of precise materials. They can ensure that in whatever application these materials would be used for, they would get the job done, offering unprecedented levels of stability to various structures and systems.

Sustainable industry growth

There seems to be nothing stopping the metal production industry in its tracks. As long as the mining sector remains steady, you can easily predict the growth of the metal manufacturing industry in 2020 and in the next few years to come.

Despite the volatility brought on by the COVID-19 virus, the manufacturing sector is slowly picking up. Those involved in the entire supply chain in this sector would likely have understood the need to adapt to the changes brought on by a halt in operations, facility shutdowns, and disruptions in supply procurement.

As this sector is continually made aware of the environmental impacts that take place in manufacturing, there would also be a focus towards coming up with new solutions that address climate change-related issues. This can be done through sustainable efforts that aim to contribute to the current climate change response, such as reducing emission levels and use of more energy-saving equipment.

Expansion into different sectors

You cannot underestimate just how valuable the metal fabrication industry is, towards fast-tracking economic recovery. Especially now that the world has been faced with an onslaught of disturbances due to the virus, there should be a renewed focus towards already-existing industries that show great potential. The metals industry would also do well to expand into different sectors that have yet to tap into this potential.

Metal manufacturing doesn’t have to limit itself only to the provision of materials for construction and industrial use. They can venture into sectors such as healthcare and hospitality. As mentioned before, there is a need to adapt to the changes brought on by the pandemic — the steel or metal sector can respond through the supply of materials. These high-end and durable materials can be utilized in the construction of isolation beds for quarantine facilities, or as barebones structuring to add support for different technologies that may arrive in the future.

3D printing

In line with expanding to the healthcare sector, for example, another metal trend that may arise in 2020 has to do with the 3D printing industry. This can eventually become a low-cost way of producing large volumes of personal protective equipment. These materials are severely lacking in many healthcare facilities — not just in the country, but globally as well. Metal 3D printing can provide a long-term solution for numerous problems, including this one.

3D printing is also used in combination with other techniques, such as laser cutting. It typically involves a small sample, or amount of metal powder that is placed on a platform. The sample is then scanned and the information that is transmitted by a computer then leads to the fusion of these metal particles in order to generate layers that correspond to the targeted model, or component.

Key Takeaway

The outlook for steel products and the metal fabrication industry as a whole, is marked by advancements and focus towards sustainable growth. There are many processes that have yet to be discovered by many industries, many untapped areas of potential that haven’t yet been brought to light.

The forecast for metal production in this year isn’t necessarily negative, despite the effects of the pandemic. In fact, it will slowly pick-up as sectors start opening up and begin investing into the manufacturing business.