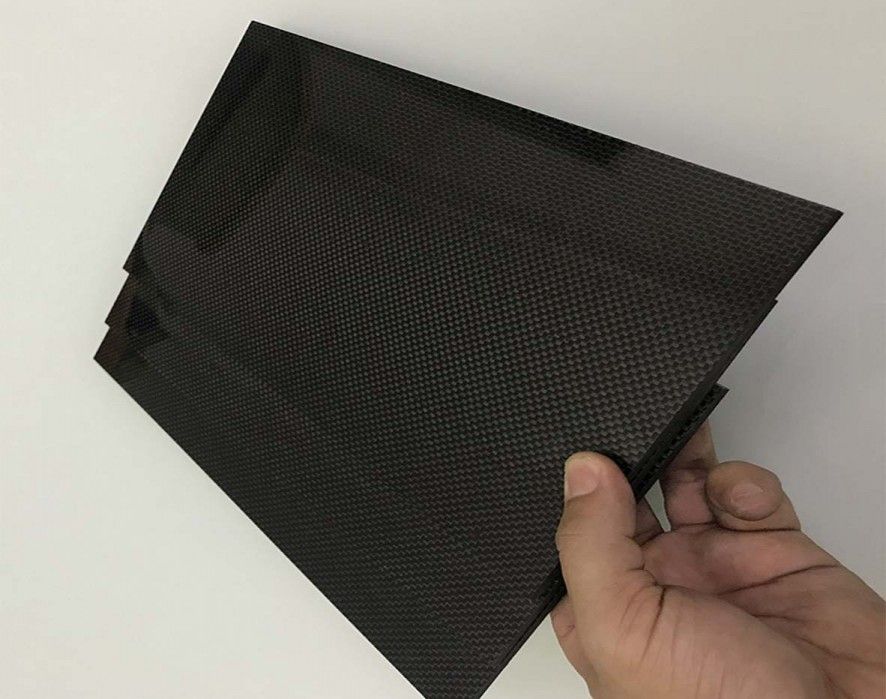

The premise behind the carbon fiber panels we sell is lightweight and good looking structural material, cosmetic enhancements and protection from damage. The panels we sell are an advanced composite material - a material of choice for the aerospace, automotive racing, marine and sporting goods industries.

What is carbon fiber?

The premise behind the carbon fiber panels we sell is lightweight and good looking structural material, cosmetic enhancements and protection from damage. The panels we sell are an advanced composite material - a material of choice for the aerospace, automotive racing, marine and sporting goods industries.

Advantages include:

Very high strength to weight ratio

High resistance to fatigue

Harmonious damping properties

Impact strength

Low coefficient of thermal expansion

Resistance to corrosion.

"Composite" is a general term meaning an assembly of dissimilar materials used together. They are carefully engineered and uniquely suited to be extremely strong and surprisingly lightweight. These materials consist of a resin matrix and fiber reinforcement.

We use high quality MGS epoxy resin that is approved for use in the manufacture of certified aircraft parts. We also use a variety of the major fabric reinforcements from leading carbon fiber manufacturers such as Grafil Inc, Hexcel and Toray

T700 carbon fiber sheet

Why is it more expensive than products made from conventional materials?

There are three main reasons:

1. all primary raw materials are expensive.

2. the construction of each product is complex, there are many materials used to make the final product.

3.The design of each product is labor intensive and must be done by a qualified composite engineer. There is no way for machines to build the products

Be warned - many of the "carbon fibers" on the market today are WRONG, but not ours! Read more about it here.

How soon will I receive my order?

Most of the carbon fiber sheets we sell are made to order, so it may take up to a few days for your order to be ready to ship. Mixed bags and sample packages can usually be shipped within 24-48 hours. Shipping is usually by US Priority Mail (however, the shopping cart uses UPS calculations for shipping). International shipments are usually shipped via Global Priority Mail or Air Mail.

Unfortunately, we are NO longer accepting UPS 2-Day or faster orders. All carbon fiber orders are shipped as standard shipping.

I want a custom size that I don't see in your listings, how can I get a quote?

For your convenience, we have set up a special order page that will provide you with real-time pricing and weight information for just about any carbon fiber panel you need - up to 4 x 8 feet!

If you want to place a very large order or have special requirements, contact us with your request.

How can I measure the thickness of these plates?

The panels we have come in various thicknesses from .013" to .125". To give you an idea, we have provided the following references:

.013" (0.33 mm) is pretty thin, only about as thick as 2 pieces of paper stacked on top of each other. It is easy to cut with scissors and can be bent around a cylinder without much effort. It is most commonly used for cosmetic applications and installations where appearance is more important than protection and stiffness.

0.020" (0.5 mm) is about as thick as if you stacked 5 sheets of paper on top of each other. You can cut it with a good pair of scissors and it will flex, just not as easily as .013. Good for applications that need a little more protection, but still need to look good.

.032" (0.8 mm) starts to get pretty stiff. For reference, a standard audio CD is 0.048", so it's a little thinner than a CD, but try bending a CD and imagine the 0.032 carbon fiber sheets being TWICE as stiff as the CD! This material is great. Cut it with a saw, or you may be able to get away with tin snips.

0.050" (1.27mm) is just under 1/16" thick, it's a little thicker than a standard CD. It is quite stiff and does not bend easily around a surface. It is an excellent material for small structural applications or impact resistance.

0.125" (3.175mm) is a full 1/8" thick. Very durable and stiff. Try bending it and you will understand that composites are amazingly strong and durable. Great for structural material. You will definitely need a saw to cut this material. Finish the edges with sandpaper.

0.25" (6.35 mm) is a full 1/4" thick. This is some serious material. There is no way you can bend it with your hands. For most purposes, this thickness is way too thick, but some of our customers have requested it to cut out small carbon parts.

How do I cut it?

For the thinner pieces (.020 and smaller), you can really just use a good pair of scissors. You might be able to cut thicker material with tin snips, but the optimal method is to use a band saw or scroll saw. Fast cutting, like with a jigsaw or circular saw, tends to create a lot of dust and can leave a less smooth cut, so slow cutting is usually better. If you use a saw, it's a good idea to protect the shiny surface from scratches with some masking tape or something similar. Finish the edges with 100-grit sandpaper to get rid of the rough spots, then resand with 400-grit. If you're really discerning, you can use a waterjet or laser cutting service. (Although laser cutting carbon fiber tends to really stink because the material burns!)