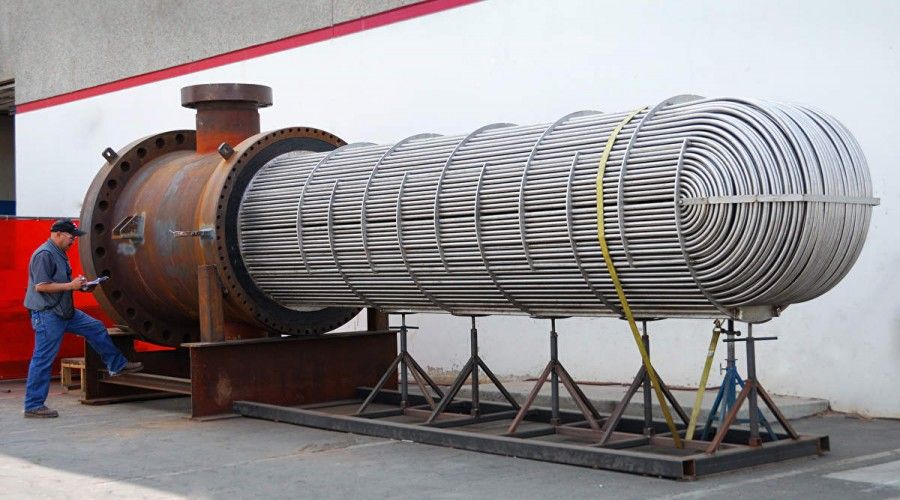

These gadgets are basic for refrigeration, power age, air conditioning, and that's only the tip of the iceberg, and come in numerous shapes and sizes that can both present heat or expel it. Understanding what makes one heat exchanger interesting from another is frequently troublesome, so this article will assist perusers with increasing an initial information on one of the most mainstream heat exchangers, the shell and cylinder heat exchanger. This article intends to uncover what shell and cylinder heat exchangers are, the manner by which they work, what types exist, and how they are utilized in industry.

A Shell and tube heat exchangers in UAE is a framework used to move heat between at least two liquids. Heat exchangers are utilized in both cooling and heating forms. The liquids might be isolated by a strong divider to forestall blending or they might be in direct contact.

Heat Move Effectiveness Of The Blender/Heat Exchanger

The one of a kind structure of the Shell and tube heat exchangers in UAE offers ascend to phenomenal abilities, which are especially clear with complex cooling errands. Indeed, even pseudoplastic (non-Newtonian) or thixotropic media can be blended with no issues over a wide temperature run and with critical contrasts between the thickness at the delta and outlet or between the temperature of the item and the coolant. Attributable to its capacity to blend the item homogeneously for significant stretches, the blender/heat exchanger precludes the danger of mal-dispersion, which is a feared wonder with other heat exchanger types.

Fluitec Multitube Heat Exchangers

Multitube Shell and tube heat exchangers in UAE with blending components in the multitubes are perfect for item viscosities among 50 and roughly 500 mPas. Different static blending components can be introduced in the multitubes relying upon the heat move application. These components increment the heat move from the item to the cylinder divider, so littler sizes can be acknowledged than if the multi tube heat exchanger has no blending components. Multitube heat exchangers are not appropriate for processes were the living arrangement time is basic or for cooling assignments where the thickness increments essentially (danger of maldistribution).

Fluitec Sterile Heat Exchanger

Fluitec sterile hardware is uncommonly built for the best conceivable partition between the essential and optional media, with for all intents and purposes complete drainage on the item side. Fluitec sterile shell and cylinder heat exchangers are along these lines undeniably fit to CIP/Taste plants Shell and tube heat exchangers in UAE. An extraordinary surface treatment method, in addition to consistent funnels with electropolished insides, brings about surface unpleasantness as low 0.4 µm on the item side. Fluitec builds the sterile-heat exchanger in permit of Calorifer Designing AG.

Heat Move Proficiency Of The Blender/Heat Exchanger

The novel plan of the Shell and tube heat exchangers in UAE offers ascend to phenomenal capacities, which are especially apparent with complex cooling undertakings. Indeed, even pseudoplastic (non-Newtonian) or thixotropic media can be blended with no issues over a wide temperature extend and with noteworthy contrasts between the consistency at the delta and outlet or between the temperature of the item and the coolant. Attributable to its capacity to blend the item homogeneously for significant stretches, the blender/heat exchanger precludes the danger of mal-dissemination, which is a feared wonder with other heat exchanger types.

Drifting Head Exchanger

The drifting head exchanger consolidates the best parts of both the past structures. One finish of the tubes is held fixed to the lodging with a fixed tubesheet, however the opposite side is allowed to extend utilizing a part known as a coasting tubesheet. This part permits the tubes to extend with expanded temperatures, without expecting to twist the channels. Administrators can get to the tubes for simple cleaning, while likewise having the option to make a high-temperature contrast unafraid of breaking the gadget. The drifting head exchanger is, hence, the best heat exchanger as far as effectiveness and upkeep, however normally comes at a greater expense.

Details and Choice Standards

These sorts of heat exchangers are utilized all through industry in substance plants, power generators, coolers, and that's just the beginning. Secluded heat exchangers can be purchased that will work in most little scope circumstances, yet huge scope exchangers require extra legwork Heat exchanger manufacturer. They are constructed dependent on the procedure they are a piece of; thus, they should be process-structured so their particular plan parameters can be coordinated with TEMA-standard parts. Along these lines, purchasers can arrange their heat exchanger and realize that it will work impeccably in their application. Heat exchanger fabricators have made procedure datasheets that help start this methodology, and a model is offered underneath to show what sort of data is required: