The flow meters are advantageous as they improve accuracy. They also indicate flow and control the amounts of the substance passing through a pipe at a unit time.

A flow meter is an industrial tool used to measure the volume or mass of substances. It measures the volume of gas or liquid. It works by gauging the amount of liquid, steam, or gas passing through pipes. The specific application defines the type and capacity of the flow meter to be used. To choose a flow meter type to use, you must know the gas or liquid to be measured and the maximum and minimum flow rate. Where products are sold or purchased based on meter reading, absolute accuracy is critical.

The types of flow meters used in industries include;

Coriolis Flow Meters

The first flow meter of this type was designed in the 1950s. However, its first operation was in 1970. It has two tubes with thin walls. When material flows through these tubes, they create inertia causing the tubes to twist. The number of twists is used to calculate the mass flow rate. The twists cause the sensor to make a flow signal. Coriolis flowmeters are very accurate. They are used in measuring a wide range of petroleum products like natural gas and crude oil. They are also used in wastewater treatment facilities. It is an advantageous type of flow meter to use as it is easy to maintain.

Differential Pressure flowmeters

Differential pressure flow meters measure changes in pressure. They identify the speed of flow. These flowmeters use constriction to lower the flow and pressure of material inside the pipe. When no moving parts are involved, a differential pressure flow meter is the best choice.

These types of flow meters are used in chemical manufacturing and plain water testing. They are advantageous because their cost is low.

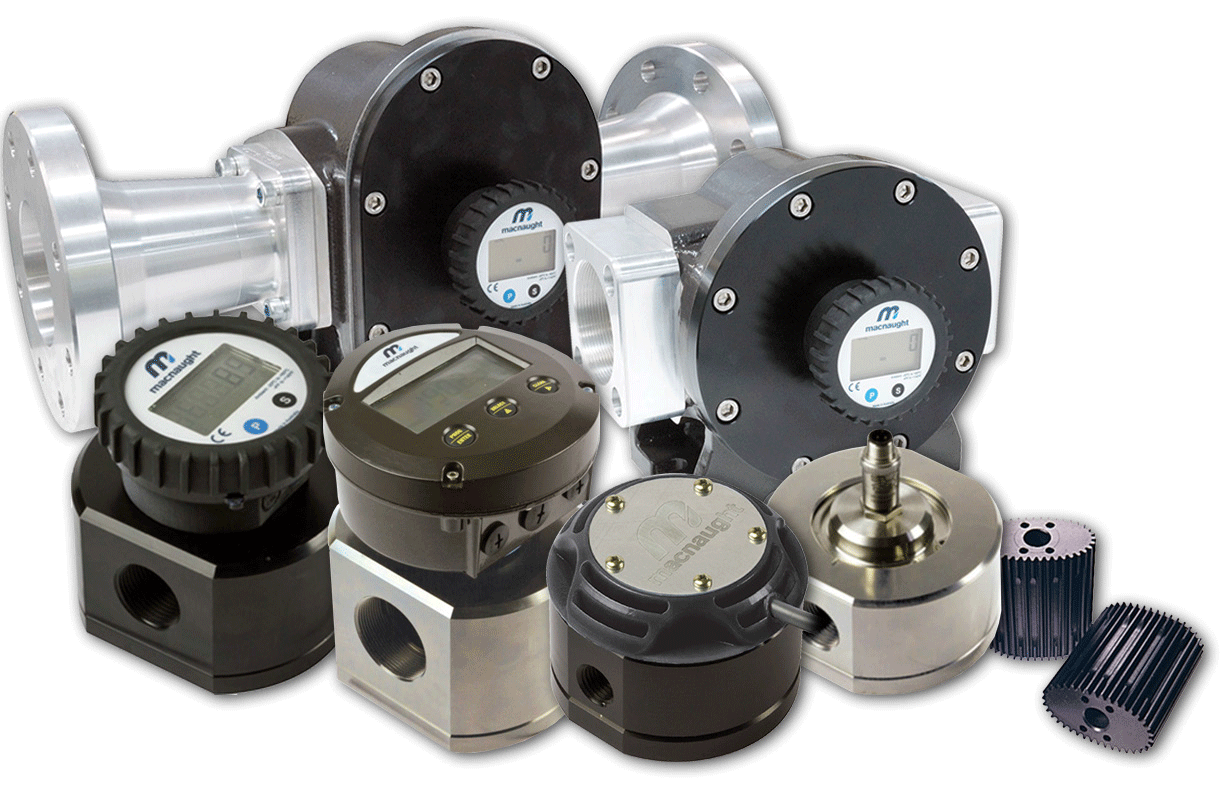

Positive Displacement Flowmeters

These types of flow meters gauge the volume in a fluid. They count the number of accepted isolated volumes. The isolated volumes are adhesives and paints. The output is directly related to the volume passing through the flow meter. These types of flow meters are mainly used in food processing and chemical industries. Their advantage is that they are highly accurate and have a long service life.

Turbine flow meters

This type of flow meter uses a mechanical rotor. The rotor is attached to a shaft inside the pipe. It then measures the flow of liquid, steam, or gas passing through the pipe. The rotor spins as the material passes through the tube. It rotates with speed, depending on how fast the substance is passing. The speed is deduced by the sensors. The sensors then transmit the signals; hence the volume of the substance flowing in is determined. Turbine flow meters are cheap to buy. They give accurate readings. These flow meters are commonly used in industries to measure the amount of gas or water in buildings.

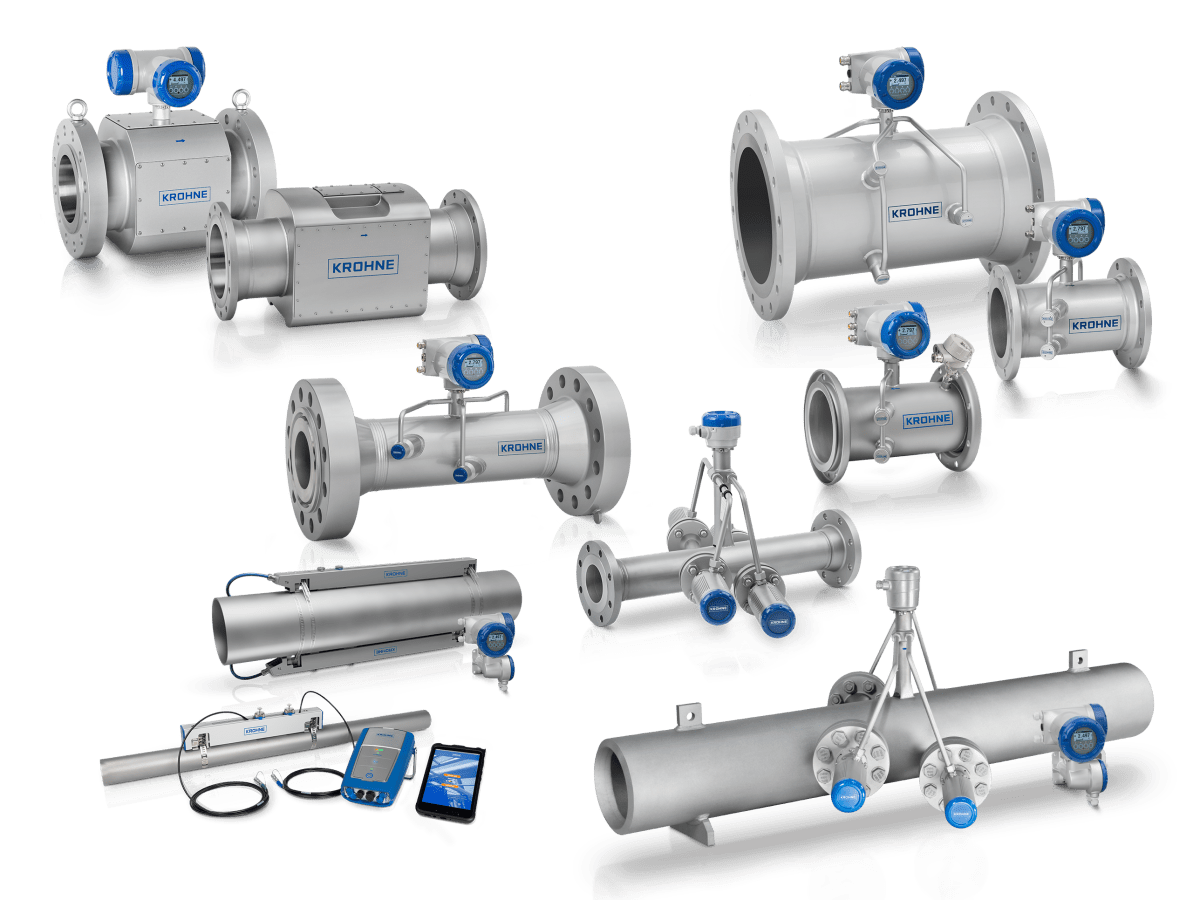

Ultrasonic Flowmeters

They measure the pace of the fluid running through a pipe. They use sound waves. A change in the frequency will be noticed when the speed of the fluid increases. Ultrasonic flowmeters can be used to gauge both the pace of the liquid inside and outside the pipe. These flow meters are highly used. Ultrasonic flow meters are affected by the properties of the substance. They can be influenced by temperature, density, viscosity, and suspended particles depending on the exact flow meter. They are easy to purchase and easy to maintain.

Open flow channel Flowmeter

As the name suggests, these types of flow meters are ideal for measuring substances in open channels. The open channel comes about when the flowing material is open to the free surface. The gauging of liquid in open channels includes V-notch, weirs, and flumes. They are dam-like structures. The cross-section of the low is determined by the depth of the pipe or channel and shape that the fluid is flowing through.

Mass flowmeters

The mass flow meters are also known as true mass flow meters. They are the perfect choice when precise measurement of the mass rate of a liquid is needed. They are used for the direct measurement of mass flow. They are largely used for measuring liquids whose viscosities vary with velocity. They are highly accurate and reliable over a wide range of pressures. The common mass flow meters types are Mass Gas Flow Meters and Thermal Mass Flow Meters.

Conclusion

Flow meters are of great benefit in industries. The industries put to use a lot of liquid gas and steam. Hence measuring these fluids is crucial to them. The flow meters are advantageous as they improve accuracy. They also indicate flow and control the amounts of the substance passing through a pipe at a unit time. Flow meters are unaffected by pressure, temperature, and viscosity. They also operate in both flow directions; forward and reverse.

*********eal789987@gmail.com

Thanks for sharing. I found a lot of interesting information here. A really good post.Vegeta green sab leather jacket