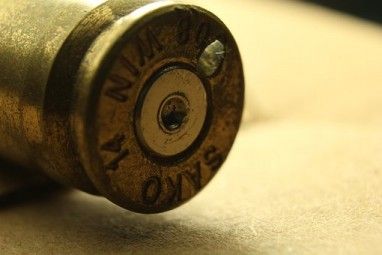

high brass shotgun shell

Reloading your own ammunition is an option any avid shooter should look into. With the high cost of ammunition, reloading can greatly lessen the expense of a trip to the range. There are a few initial start-up expenses like the cost of the various apparatus necessary to perform the job properly and the price of materials such as powder, bullets, primers and powder. While the cost of the materials cannot be redeemed, the expense of the apparatus can be made up in a short period of time at the savings that reloading your own ammunition supplies you over the expense of factory loads.

There are three basic actions to the reloading process, and every step requires particular tools. The most significant of these tools are naturally the press and the expires. The media may vary in price from around $100 to several hundred dollars based on your needs and desires. For the beginner, the best option is most likely one stage press. These are the cheapest and are employed in a procedure known as batch reloading. During this procedure a single step from the reloading process is used on an entire batch of cubes of the same caliber. Whether this batch consists of 50, 100, or even several hundred rounds, this way is the most time consuming and the repetitive nature may get monotonous. The person who is seasoned and shoots over 300 rounds per week should consider utilizing either a turret media or a revolutionary press. Using high brass shotgun shell media, several rounds can be reloaded at precisely the same time with each of those steps being performed on another shell at the exact same time. A turret media holds the various tools for every measure in a turret that's situated on the top of the press, and the turret is rotated at each step, allowing the individual to reload each case in three quick steps.

The main reason I like to batch load my gun and handgun loads is twofold. The initial step involves resizing and de-priming the spent cartridge. This is done with a sizing die as a plunger expels the primer. This procedure moves the brass. As a result, the more a cartridge is reloaded, the longer it will become, and the thinner the instance walls become. I love to look at my case spans at this time and scrutinize every case for cracks. Cracked cases are discarded, and any instance nearing the utmost tolerance levels on period are trimmed at this time. I also prefer to clean out the primer pocket of any carbon deposits or residual powder in the preceding primer.

The next step is priming the instance. Even though this can be carried out with the press, I prefer to use a hand primer. Lee offers several good ones. They come with a primer holder which automatically feeds the primer into the situation that's held at a case holder and an easy squeeze of the hands and it's done. Depending upon the visual appeal of the instance, I may decide to throw the whole batch into a buffer at this point. Leaving them in the buffer for one hour or two will lead to highly polished brass and a factory appearance for your reloads. Make sure you prime your instances before buffering though, or you are going to be picking pieces of cork from the primer pocket.

The next step entails charging the case and seating the bullet. This is the vital part of the process. I've got a powder measure and a powder scale with which to quantify the desired powder fee for the planned load. I powder bill my loads at the rate of about 50 at a time. It is important that you're not distracted at this moment! Double prices can have catastrophic results. With my powder I will assess my powder fees about each ten loads. This can be an important thing to do if you are reloading close to maximum loads, but it will also help to provide consistency for your reloads.

The final step entails venting the bullet. The press is used for it. Make sure that you ask your reloading manual as to the proper seating depth of the bullet used. It is a good idea to have a bullet puller. Mistakes can sometimes occur. I use an effect puller by RCBS. You simply place the cartridge in the top, screw on the cap to hold it in place, and apply it like a hammer. The bullet comes out and is caught in the mind of the puller. The case will have to be recharged. But because both the bullet and the powder are recovered, they can both be used again.

For more information: Click here