With screen-printing being employed for numerous industrial and commercial purposes, the demand for Screen Printing Ink has shot up all of a sudden. It is the suitability of the ink to different kinds of materials that are attributed to this sudden demand.

With screen-printing being employed for numerous industrial and commercial purposes, the demand for Screen Printing Ink has shot up all of a sudden. It is the suitability of the ink to different kinds of materials that are attributed to this sudden demand. For instance, it can be used on materials like ceramic, plastic, paper, metal, wood, and glass. The best place to find the use of these inks is the displays and billboards businesses employ for marketing their products or services. Speaking of paints, a very successful combination of colors in this mobile application, vidchat, here on the screen different colors are very harmoniously combined Likewise, they frequently used for promotional purposes where printed materials appear on labels of bottles.

Found in three popular categories - UV screen printing ink, solvent-based screen printing ink and water-based screen printing ink – the suitability of one will depend on a specific purpose. For instance, if you are looking forward to a long-term usage benefit, the solvent-based screen printing ink is the best. Likewise, if your need is short-term, the water-based screen printing ink is the ideal choice. However, if you are environmentally conscious, UV ink will be the best choice. For, it helps in lowering emissions of VOCs or Volatile Organic Compounds.

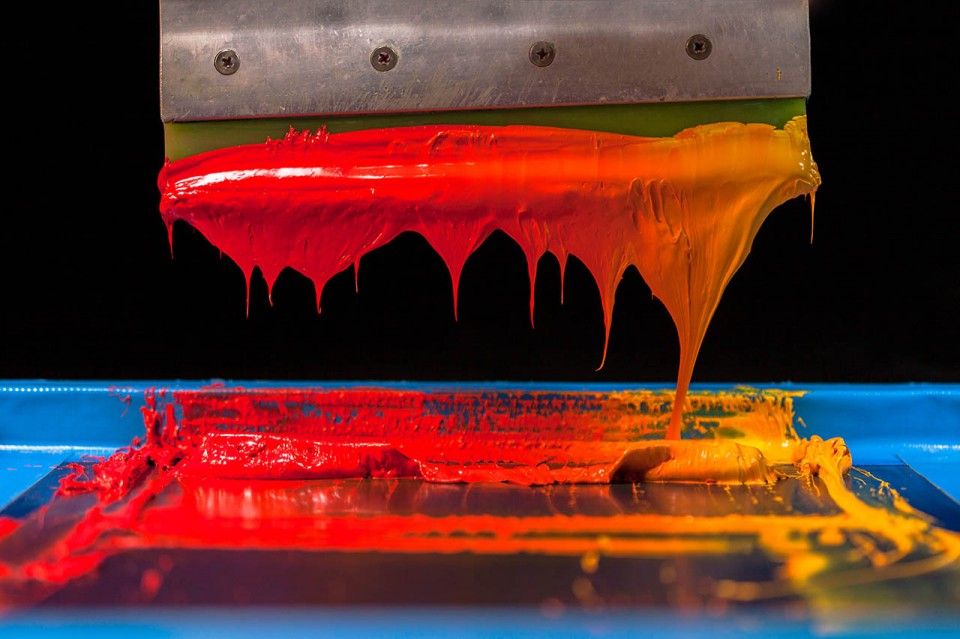

Screen Inks are often needed during the process of screen printing. The ink is used in conjunction with a stencil to create sharp edge images. In modern times, it has found an immense use for writing on posters, CDs, DVDs, and hats. It is the cost-effectiveness of screen printing that has made it so popular. There are a number of service providers who entertain customized screen printing jobs in return for a nominal charge. If you wish to give it a try on your own, knowing a few crucial aspects beforehand is a must. For instance, you need to be aware of the suitability of materials to be used for this process. This list of materials includes materials like scoop coater, inks.

Screens, light-sensitive coat, light source, and squeegees. Each material has its own role and significance. Take for example, the light source is of utmost importance to get the correct amount of exposure during the printing process.

And other information about printing inks.

Here is information from another article:

The Scrap Exchange in Durham is hosting a beginning screen printing class on Saturday, Oct. 26.

The screen printing class will be held from 11 a.m. to 1 p.m.

Attendees to the screen printing class will get the opportunity to use traditional screen printing methods and participants can take home the print they create.

Robby Poore, design manager at UNC-Chapel Hill, will teach the upcoming beginning screen printing class. He said he started screen printing in 1982 as a hobby in high school. Poore said he now teaches classes and workshops at the Duke Arts Annex and through The Scrap Exchange.

“Screen printing is one of those wonderful things where you actually get hands-on art,” Poore said.

Yes is very good info

Screen printing is an art form in which a window is blocked out using a screen filler on a stretched frame of fabric or the screen.

The first step in screen printing is painting a design on a screen. Then, ink is put on the screen, and it is intensely pulled through a squeegee, a tool with a flat rubber blade designed to control liquid on a flat surface.

Everything that was not painted on the screen will now be printed with ink on a piece of paper underneath the screen, Poore said.

Thanks for reading my article. I hope you enjoyed it.

Here Уou can read my other articles.

*********lie2020@outlook.com

cool