Pneumatic systems utilise so many varieties of components which are used to control the volume of air, the pressure, and the rates by which it passes within the systems. Most commonly used components to control that air pressure is pneumatic valves. It is available in different kinds of ways which are care properly for those valves.

Pneumatic systems utilise so many varieties of components which are used to control the volume of air, the pressure, and the rates by which it passes within the systems. Most commonly used components to control that air pressure is pneumatic valves. It is available in different kinds of ways which are care properly for those valves.

Most of the industrial fields use these pneumatic systems to pass the power which is based on the compressed air that used to holding the force into the system.

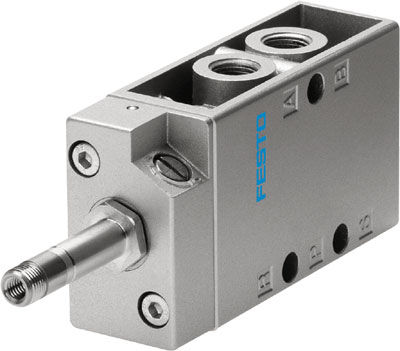

Applications of diesel engines use pneumatic pressure valves to power their tools. It is the main component which is placed in all kinds of the diesel engine to work. One of the essential valves are directional control valves that either repress airflow in the devices or control the specific direction of that, are a significant kind of pneumatic valves. If you are searching for valves you can order online Festo Pneumatic Valve at the best price.

The classifications of functional directional control valves are based on the device by which gates are opened or closed; the flow paths are formed, also the amount of entry and exit ports in this valve.

Different Types Of Pneumatics Valves Are:

Open Versus Closed Resting State:

Spring valves appear with a part of nuance which is similar to two-way directional and spring offset valves. Well, in this, there are just two positions which valve can find if the actuator is not active even though they are closed or opened. Here when the system valve is an open state, then the air can flow freely throughout the complete valve. But, When it is closed, the airflow will be blocked.

Spring Offset:

Know how specific airflow directions are switched and what classifies to differentiate that pneumatic valve. For example, in the two-way directional valve, the valve will remain either open or close; therefore, the airflow will either blocked or enabled.

The valve spool will be pushed into position through an actuator that used to provide one port to find an open or closed position. To return the valve to its previous position, these valve spool need be released. That can be done by spring. The directional valves listed as two-way, which work in a particular way that described, are related to spring offset valves.

Four-Way Directional Valves:

These type of valve and valve uses all the direction to control the fluid flow and inside an hydraulic application, it also controls various other directions while to the motor is moved. Four-way valves are the sliding-spool model. They consist of four ports:

• One of the pressure ports will use to connect the pressure line.

• Another one is return or exhaust port which used to be connected for a reservoir.

• Another two working ports used to connect, through lines, and by actuating unit.

Three-Way Directional Valve:

There are about four kinds of 3-way solenoid valves. All of these valves are used for various purposes. The main valves include 3-way normally open, and 3-way normally closed. These valves will vary just by the case that one must usually open passageway, and then another must often close one. This 3-way valve needs for several complex functions; both are used either the 3-way directional control, as well as the 3-way multipurpose valve, are used.

Two-Way Directional Valve:

In these Festo Valve, the air will be flows with the help of opened or closed ports. When the valves are closed, the air cannot flow. The first port valve can pass the air and the opposite direction from the second port when the ports remain open.